This Is How 5G Network Will Transform Mining

The mining sector faces great challenges in digitalizing its operations. It is one of the most disinclined industries to change, confronting severe restrictions generated by the operation itself and the conditions that it develops in. However, in Latin America, this industry is beginning to understand the importance of digital transformation and is seeking alternative solutions for the barriers that set them back.

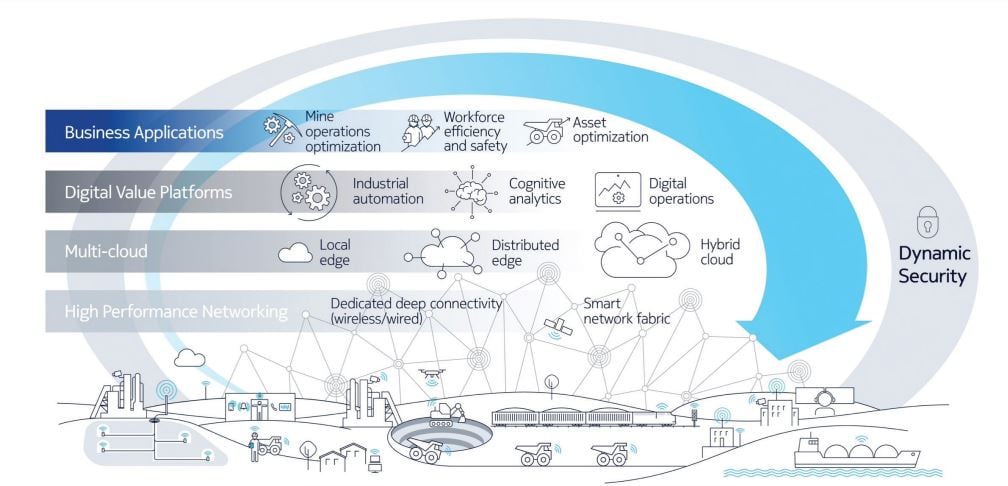

Addressing this process requires improvements in infrastructure and communication networks. The location of work zones and conditions such as distance from urban centers or underground work that make it imperative to use networks with greater accuracy and latency, to accompany systems and make decisions with less risk and greater opportunity. 5G networks are needed to boost transformation.

A study from Nokia and Omdia, points out that 5G technology has the potential to generate up to US$9 billion in productivity improvements in Latin America by 2035. On the other hand, Ericsson estimates that the global smart mining business will triple its size by 2025, where 25% of operations will be automated in mines.

Once established, the network speed of installations will increase tenfold allowing to capture 100 times more data and improve artificial intelligence applications, augmented reality and advanced analytics in their productive processes.

Among some of the developments that will have greater benefits for smart mines are:

- Self-driving vehicles. Transportation of the minerals from the extraction point to the deposits and to the processing areas represents a risk. Self-driving vehicles can prevent accidents and injuries to workers, it also reduces the consumption of fuel and increases efficiency.

- Real time monitoring. 70% of damage to machinery could be prevented if information was collected and analyzed from machines, which would identify potential faults of wearing for specific parts. By having monitoring in real time, mining operators receive important cost reductions in maintenance

- Remote controlled drills. Remote controlled drilling can increase productivity by a large proportion as it is much faster than manual drilling. Done remotely, it only requires that the operator initiate the process and the drill then moves freely between sites.

- Inspections with unmanned drones. Drones have been used to inspect areas that have not yet been determined safe for humans after an explosion, inactive periods can be reduced by 7% and the costs to impede operations by 51%.

- Intelligent controlled ventilation. Ventilation is essential for underground operations. With automated smart systems there are benefits such as better air quality for workers, less downtime when extracting toxic gases more efficiently and a reduction in ventilation costs.

Beyond a productive environment, with the application of 5G technology in daily operations, mines would have a more responsible environmental footprint that would better the safety of its workers during an emergency on the job, for example contacting doctors and workers via satellite to provide consultations and remote procedures through any device connected to the network.

According to a survey by Business News Americas, the budgets for digitalization have dramatically increased. The large producers surveyed provided information on the reasons for that increase, they mentioned the need for remote work, automation, safety and efficiency.

Regardless of the technologies that mining companies are planning to implement, the key to final success is reliable wireless connectivity. 5G-ready cellular networks will play a key role to ease the digitalization in mining to offer a high speed connection with low lag and robust performance in high device density environments because the networks will have to manage ever increasing amounts of data.

Softtek joins you on this journey of the mining industry transformation. Contact an advisor by clicking here.