Throughout history, various reasons why the software may fail have been identified. One of the main reasons for such failures is a poor quality assurance (QA) during the development process.

The main purpose of running a quality assurance test in the software is to avoid releasing low quality products to end customers, as small errors can lead to large financial losses.

A good example of the importance of QA is Flud, a social news reading app for iPad, iPhone, Android and Windows Phone. Flud was known as the “first social news reader.” However, the launch failed due to poor quality control services.

Flud’s team’s top priority was the development process and its focus was on creating almost exclusively code, and when the product was finally released, it was full of bugs and mismatches. It didn’t matter that everything was fixed, the bad reputation and the terrible user experience prevented its success.

To keep this from happening often, the best way to provide high-quality software is to implement quality control management that provides tools and methodologies for creating error-free products.

Currently, the market size of quality management software is $6.2 billion and is expected to reach $17.2 billion by the end of 2025, with a CAGR of 13.6%.

Customer satisfaction, above all

The main reason for performing quality testing is to ensure customer satisfaction. This indicates that the tests are increasingly aligned with business objectives and that teams have a broader vision in mind.

It should also be noted that 99% of the companies use DevOps in at least some of their projects. Not forgetting that DevOps aims to deliver value to the user as quickly as possible, while maintaining high quality.

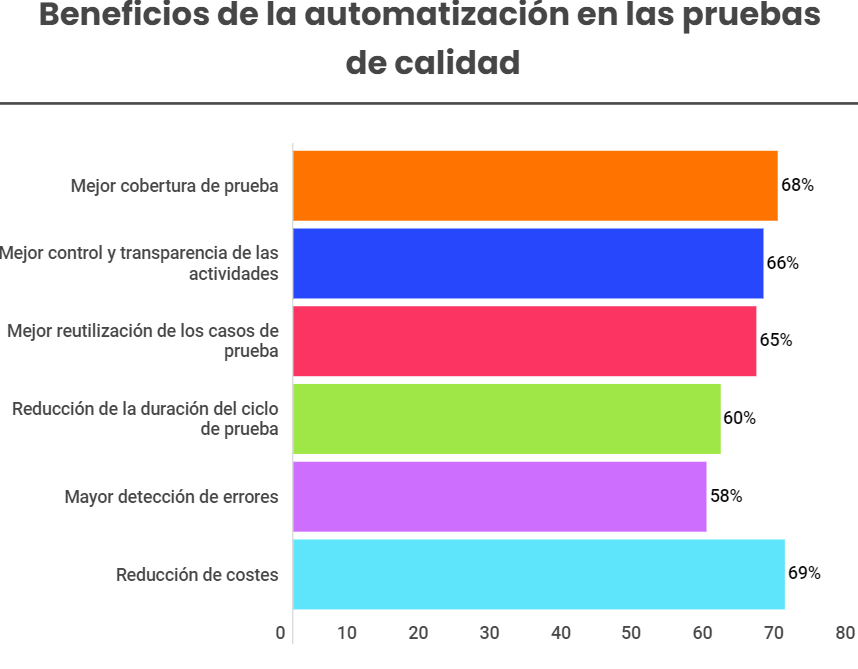

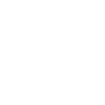

As a result, there is a need for greater automation, which is essential to speed up the testing process. However, the latest reports indicate that automation is a bottleneck that is holding back quality control and testing today.

This leads to two other important findings: AI is increasingly important in testing, and test professionals must acquire additional skills.

The importance of artificial intelligence

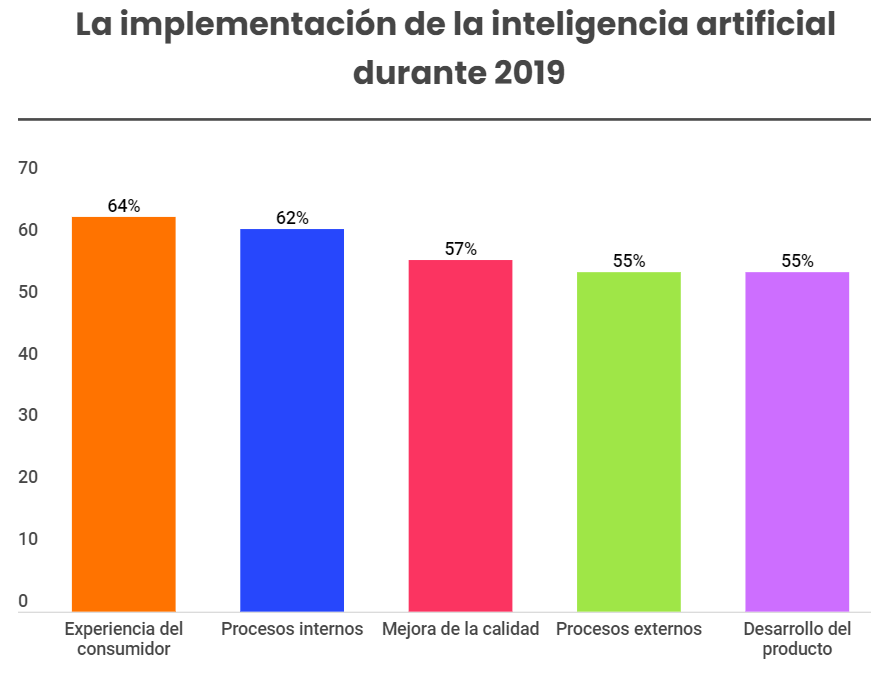

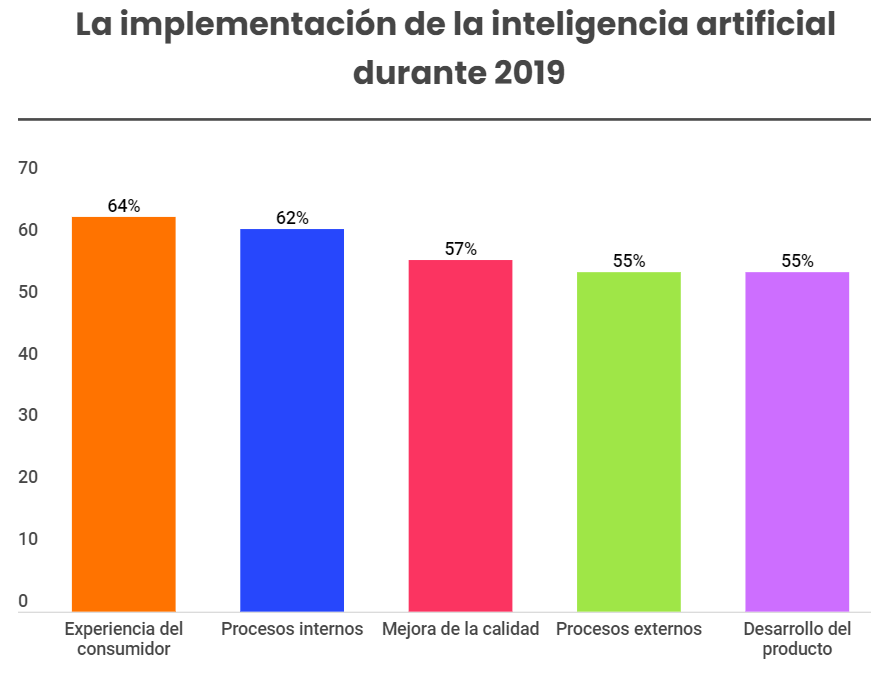

Currently, many organizations are experimenting with artificial intelligence and how it can be used to optimize the tests that need to be performed, to shorten test cycles, and increase their effectiveness.

This depends on the ability to extract information from application lifecycle management tools, test tools, and production monitoring systems, while processing that information in a timely manner.

Automating quality testing through machine learning can increase defect detection rates by up to 90%. For example, Honeywell is integrating AI and machine learning algorithms into procurement, strategic sourcing, and cost management to improve product quality.

However, this process is not easy. Although they understand the importance of AI and want to apply it, 55% of the companies have difficulty identifying where to apply AI. And, a 51% also states that it has experienced difficulties integrating AI with its existing applications.

However, AI is present in many applications and, of course, AI components must be tested. This poses a set of additional challenges, among which the professional who manages these tools must master an additional set of highly technical skills, such as mathematical optimization, neurolinguistic programming and algorithmic knowledge.

New more technical roles

It’s not easy to find professionals with these skills today, and it can become even more difficult as more organizations begin to adopt AI techniques.

- Quality control strategists: to understand how to apply AI to business. They will need to master both commercial and technical knowledge.

- Data scientists: to analyze test data and use predictive analytics, math, and statistics to build models. They must have deep knowledge and experience in data analysis techniques.

- Experts in Artificial Intelligence Testing: to participate in the testing of artificial intelligence applications. In addition to traditional testing expertise, they will need to understand machine learning algorithms and natural language processing techniques and have other highly technical skills.

While artificial intelligence requires a new skill set for evaluators and quality control professionals, it is by no means the only technological challenge for this group of employees.

New quality control skills

So far we have seen the benefits that artificial intelligence can bring in quality control, but it’s not the only innovative technology that can deliver great benefits.

Adoption of IoT technology is increasing, to the point where 97% companies have some kind of IoT presence in their products. IoT devices can capture large amounts of data, which can be sent to the cloud for processing, or processed in part or in whole on the device itself.

A great example of how AI combined with connected vision systems can improve product quality is displayed at Fujitsu’s Oyama factory. The company’s image recognition system not only helps ensure the production of optimal quality parts, but also monitors the assembly process. This dual role has significantly boosted the company’s efficiency.

Previously, the solution lacked the flexibility demanded by today’s fast-moving world. But the implementation of this solution allowed the company to quickly adapt its software to new products without the need for time-consuming recalibration. With these changes, Fujitsu reduced its development time by 80% and maintained part recognition rates at more than 97%.

On the other hand, 66% of the companies claim that they are already using blockchain technology or plan to do so over the next year. This technology is no longer associated exclusively with cryptocurrencies, but blockchain is being implemented in many systems that require greater security to record transactions.

Specifically, blockchain implementations must take into account security and data risks and mitigate the dangers associated with integration into other systems.

A mistake can result in large monetary losses. And that is, many blockchain projects do not survive after reaching the initial production state. For most, the lack of proper software testing is one of the main reasons for its disappearance.

It is estimated that more than $500 million in cryptocurrency has been lost due to a wrong code in the last year alone. Probably the most important was the legal vacuum of DAO code, which allowed attackers to exhaust 3.6 million ETH (worth $70 million at the time) of the Ethereum-based smart contract.

Therefore, hiring staff with the necessary skills can be a challenge, so it is recommended to develop skills within the current workforce through internships, specialized training and development.

Conclusions

The user is the most important thing for quality control professionals today. But without a deep mastery of new technologies like artificial intelligence, IoT and blockchain, it will be difficult to ensure that users have the superior experience they deserve.

This can be seen in all sectors, including the public sector, which lacks maturity in adopting DevOps, is talking about artificial intelligence and cognitive technologies.

Therefore, in order to successfully fulfill the strategy of placing users at the top, organizations must ensure that employees are equipped with the skills needed to test new technologies that are becoming more prevalent in products today.