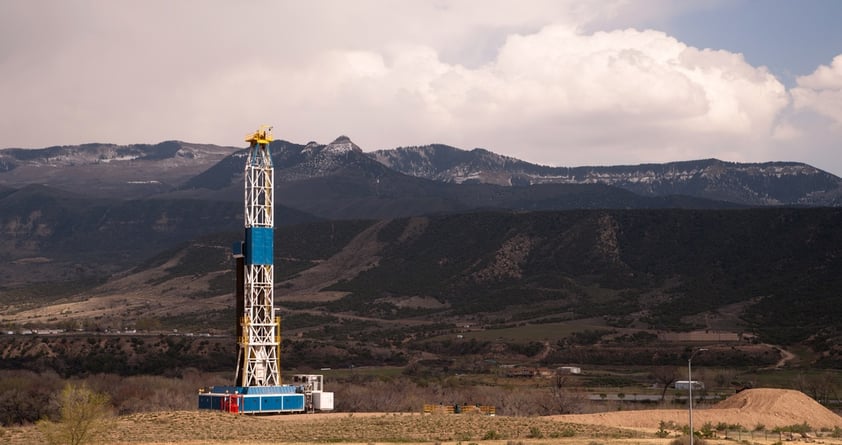

Horizontal drilling and hydraulic fracking have redefined the U.S. oil and gas production landscape by introducing myriad small and mid-size producers into the mix. To gain an edge in this increasingly crowded and competitive marketplace, these players must improve operational efficiency, anticipate breakages and minimize downtime. The technology required to achieve these aims – once accessible only to large, global firms with extensive resources – is becoming increasingly affordable. Today, producers can collect and analyze data from a network of sophisticated sensors connecting production assets that include pumps, compressors, storage tanks, separators and wellheads. The challenge lies in turning that data into insight on multiple variables such as temperature, flow, pressure or level, and then using that insight to monitor an asset’s performance and develop predictive maintenance programs.

Here are three steps oil and gas producers can take to address that challenge and develop an analytical model that extracts actionable information from mountains of raw data and drives a proactive approach to managing operations.

Assess

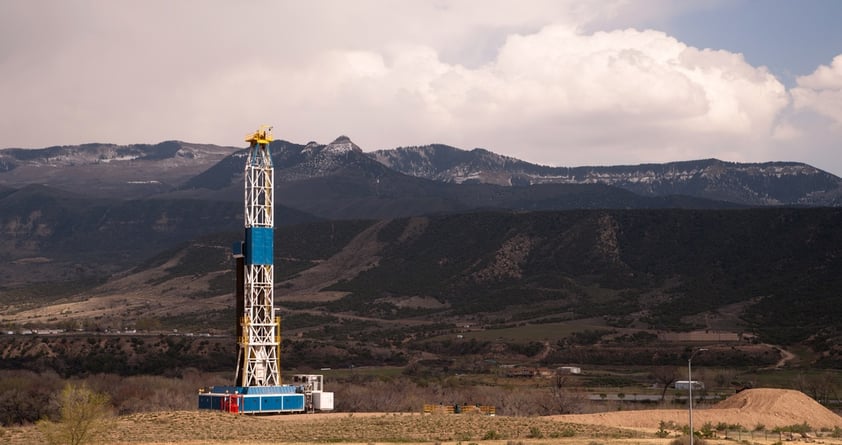

Step one is to undertake a detailed assessment of a production facility. Whether on-shore or off-shore, production facilities vary depending on the type of rig and complexity of operations. As a result, a clear understanding of the type and complexity of the production asset is imperative to effectively analyzing the data generated by various parts. Moreover, it’s essential to start small by focusing on a specific part of the operation and digging deep, rather than taking a high-level view of the entire environment that doesn’t yield any significant insight.

Expand

Once the initial Proof of Concept (POC) is completed, the assessment process can be rolled out to other parts of the operation. By collecting a series of detailed assessments of specific portions of its operation, a producer can begin to compile the building blocks of a performance dashboard that monitors production assets and provides indicators on which components are likely to fail and require attention.

Integrate

The third step to building an analytical model of production performance is to integrate the multiple operational profiles into a cohesive and holistic entity that enables the analytics that drive actionable metrics. The key is to monitor not only the performance of each specific asset, but to gauge the intricate cause/effect linkages between different assets in different parts of the operation. For example, if a sensor in one part of the operations detects a device in another part exceeding its heat or pressure limits, emergency shutdown valves are activated to prevent safety, environmental or regulatory violations. Achieving this integration requires the deployment of Internet of Things platforms that connect intelligent devices into a system of systems that enables ongoing oversight and predictive analytics.

The good news for mid-sized producers is that these platforms are becoming increasingly affordable. As a result, smaller firms can leverage technology innovation and flexible pricing models to significantly enhance their insight into production operations, as well as level the playing field relative to their global competitors.

Learn more about Softtek's IT services for Oil and Gas organizations.