Want to capitalize on Industry 4.0? Consider predictive maintenance.

Industry 4.0 holds a personal significance for me because I grew up in the West Midlands, UK, a place widely regarded as the seat of the first industrial revolution, or Industry 1.0 so to speak. For many years I was reminded of this legacy by the Boulton, Watt, and Murdoch statues prominently located in Birmingham City Center. This awareness must’ve informed my educational and career choices at the deepest level. You could say I’m a child of this evolution.

For companies interested in the operational, economic, and competitive benefits of Industry 4.0, I’ll explain why predictive maintenance (PdM) could be a great first step.

Predictive maintenance: High ROI, agile, and easy to implement

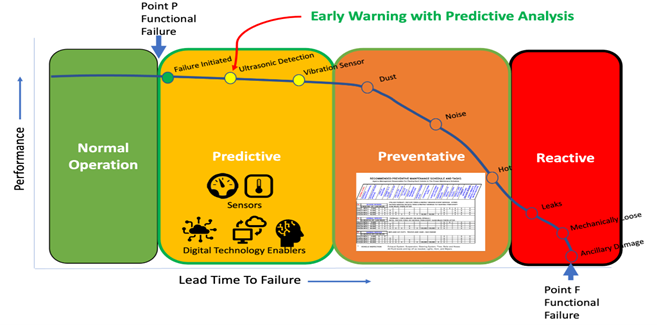

Predictive maintenance leverages sensors, IoT, AI, data science, and predictive analytics to determine the condition of equipment and when to perform corrective maintenance. This approach, along with practices and methodologies like Lean/Six Sigma, is dramatically changing manufacturing economics and creating market disruption.

Coming almost at the push of a button and making paper-based maintenance charts more obsolete by the day, PdM helps detect breakdowns early and/or prevent them all together. In other words, equipment returns to a “normal operation” range faster and stays within it for longer.

Predictive maintenance is one of the best entry-level Industry 4.0 solutions because of how expansive its business case is, relative to its cost and ease of implementation.

For starters, organizations that implement an effective PdM approach can reduce overall maintenance cost by 5-10%, increase equipment uptime and availability by 10-20%, and reduce the time required to plan maintenance by 20-50%.

Predictive maintenance savings come from a variety of areas. While its up-front project costs may be higher than planned maintenance, the short and long-term returns will improve as more data is collected. These savings can eventually become a source from which to fund further I4.0 Innovations and investments.

However, numbers only tell part of the story. Its ability to generate real-time insights and faster, more cost-effective maintenance workflows creates a platform for additional organizational advantages, including greater agility and productivity, employee job satisfaction, plant safety, and customer satisfaction. These extended capabilities are crucial for competitiveness and long-term sustainability in the face of talent scarcity, shrinking margins, and a tough regulatory environment.

Finally, installation is easy and requires minimal configuration thanks to the growing availability of plug-and-play solutions. This makes it possible for any organization to have a PdM approach up and running in no time, receiving alerts to potential problems via email or a mobile app while the sensors and AI handle the rest on a cloud application. It's also low-maintenance, as improvements to battery technology are allowing several sensor types to last up to ten years.

Conclusion

The steady addition of AI and IoT into the manufacturing operation frees up time and budget for further innovation and familiarizes organizations with new technologies and frameworks that create a competitive advantage. Most importantly, it's easy to replicate success across your operations. Due to its comprehensive business case and almost guaranteed ROI, the PdM approach to asset management is a great starting point and can create a snowball effect as organizations speed toward Industry 4.0 maturity.

.webp?width=352&name=DALL%C2%B7E%202025-03-13%2012.59.31%20-%20A%20breathtaking%20horizontal%20digital%20painting%20in%20a%20fine%20art%20paper%20cut%20collage%20style%2c%20symbolizing%20nearshore%20digital%20collaboration.%20The%20artwork%20features%20a%20%20(1).webp)